Engineered Solutions For Medical Devices Refurbished Automation

Automation Machine Manufacturers

Through Validations

Ensuring Quality Through Rigorous Validation

Quality Components

Premium Parts for Peak Performance

About ElectroAutomatización

Engineering Excellence - Medical Devices Industries

Our motivation in precision engineering is to offer tailor-made solutions with a seal of innovation. Explore the range of services for your industry.

Delivery times

Efficiency in every aspect, on-time deliveries that generate higher productivity.

Machinery parts

Automation

Control Panel

What We Do

Revolutionizing Industrial Automation

We lead the automation machine manufacturers. Our expertise spans control systems, cutting-edge technology, and automated machinery.

Our Partnerships

Services

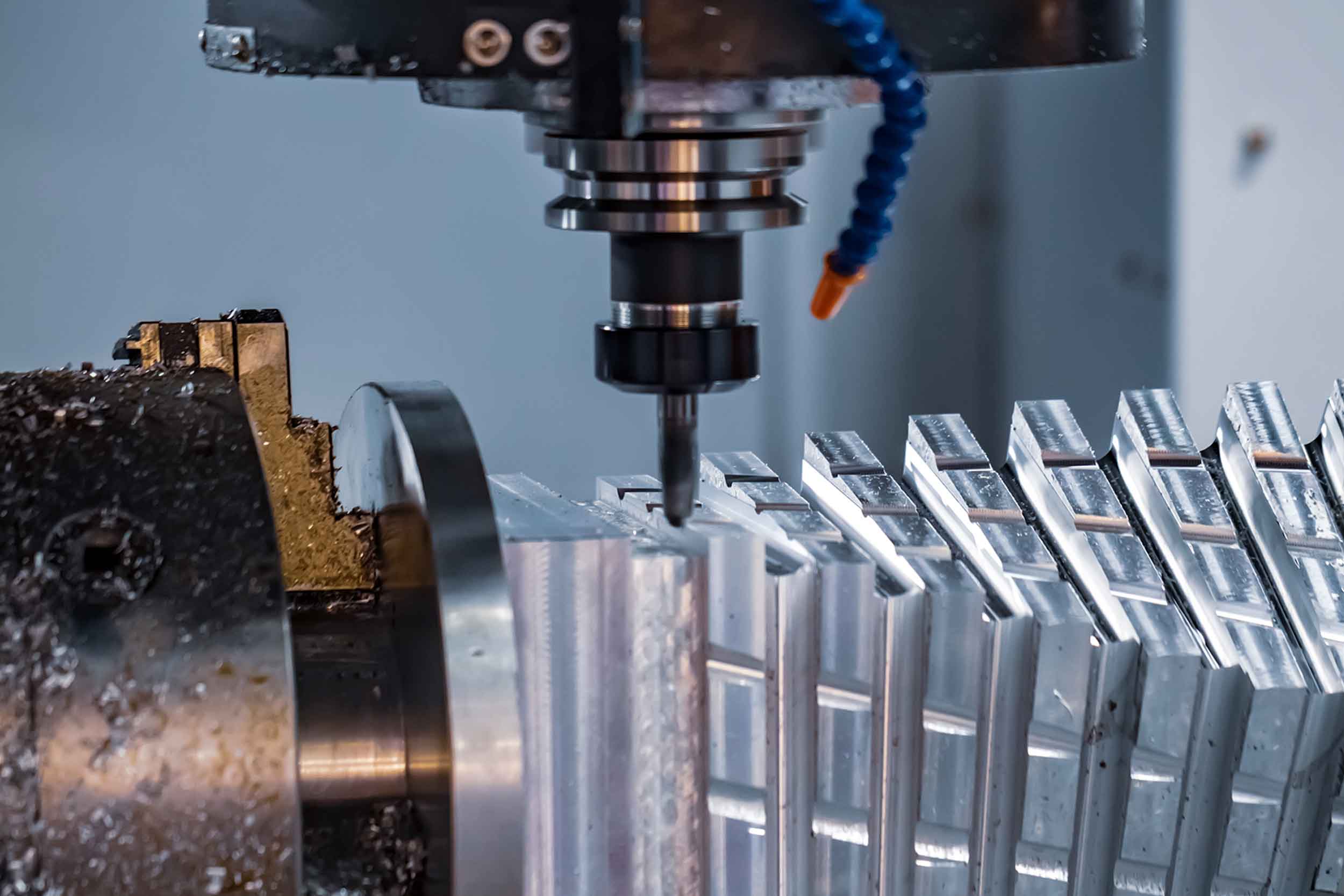

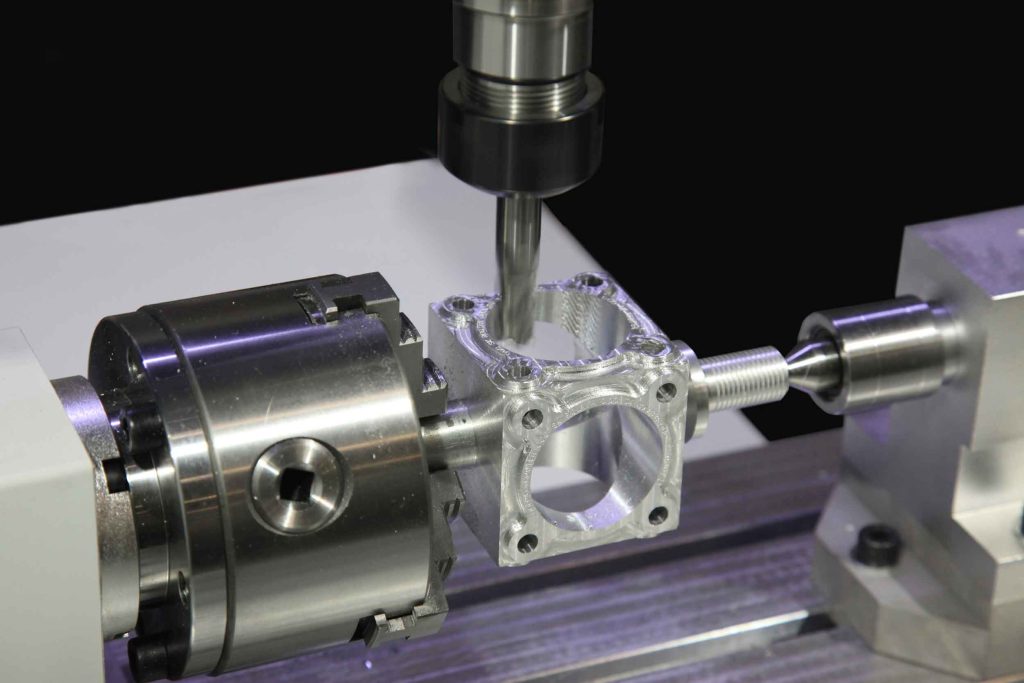

Machinery Parts Manufacturer

Manufacturer of high-quality precision parts for industrial machinery.

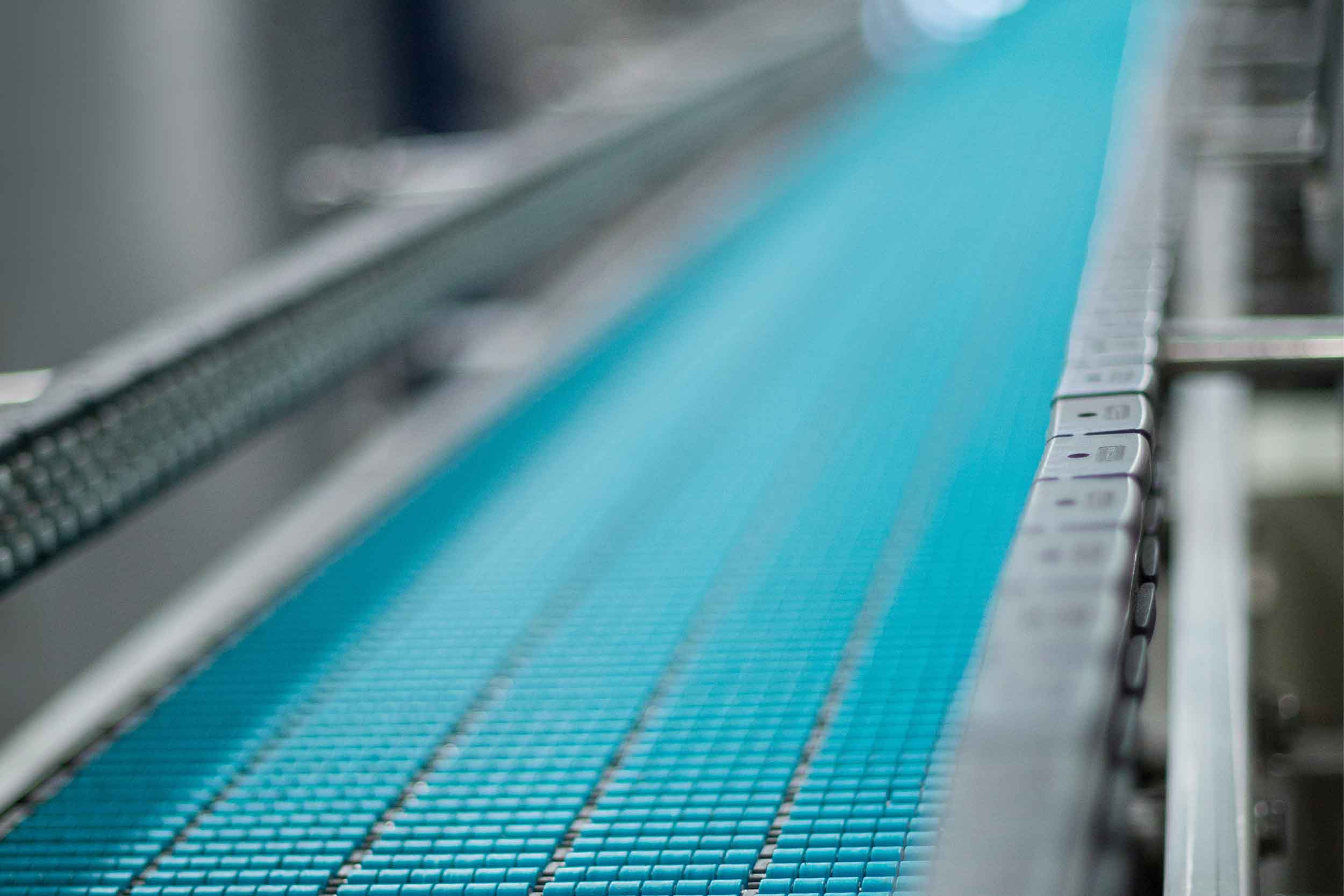

Process Automation

Improve efficiency with our advanced, customized process automation solutions.

Electrical Panel Installation

Efficient control panel design with state-of-the-art high-tech components.

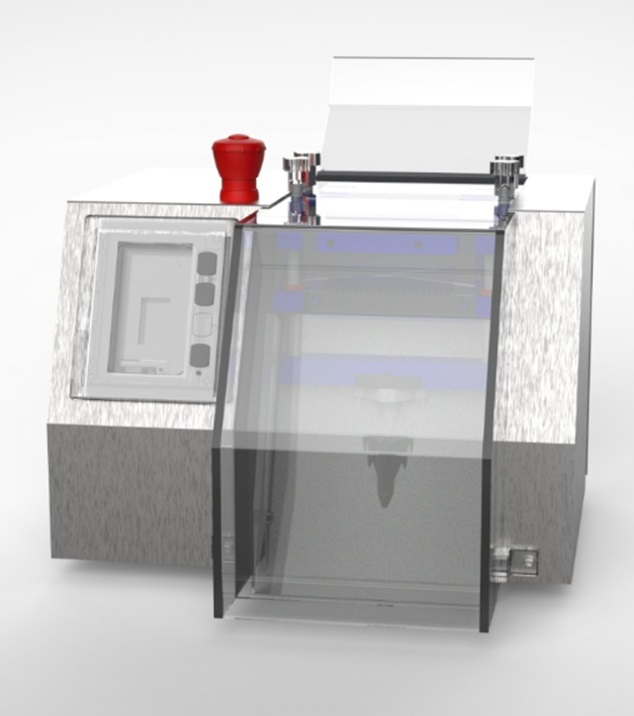

Clean Room Solutions

Optimize medical operations with our specialized clean room solutions.

Innovation Hub

The Solution: Automation machine manufacturers

Ever-evolving of medical device industry, ElectroAutomatización remains at the forefront, consistently devising tailored solutions to address challenges related to machine automation, precision, and production.

- Continuous Enhancement

- Dedication to Clients

- Unparalleled Quality

Controling all the system with modern technology

Parts Manufacturer

Our precision engineering makes crafting impeccable components tailored to your unique needs.

Industrial Automation

The optimizing operations through automation machine manufacturers create extraordinary results.

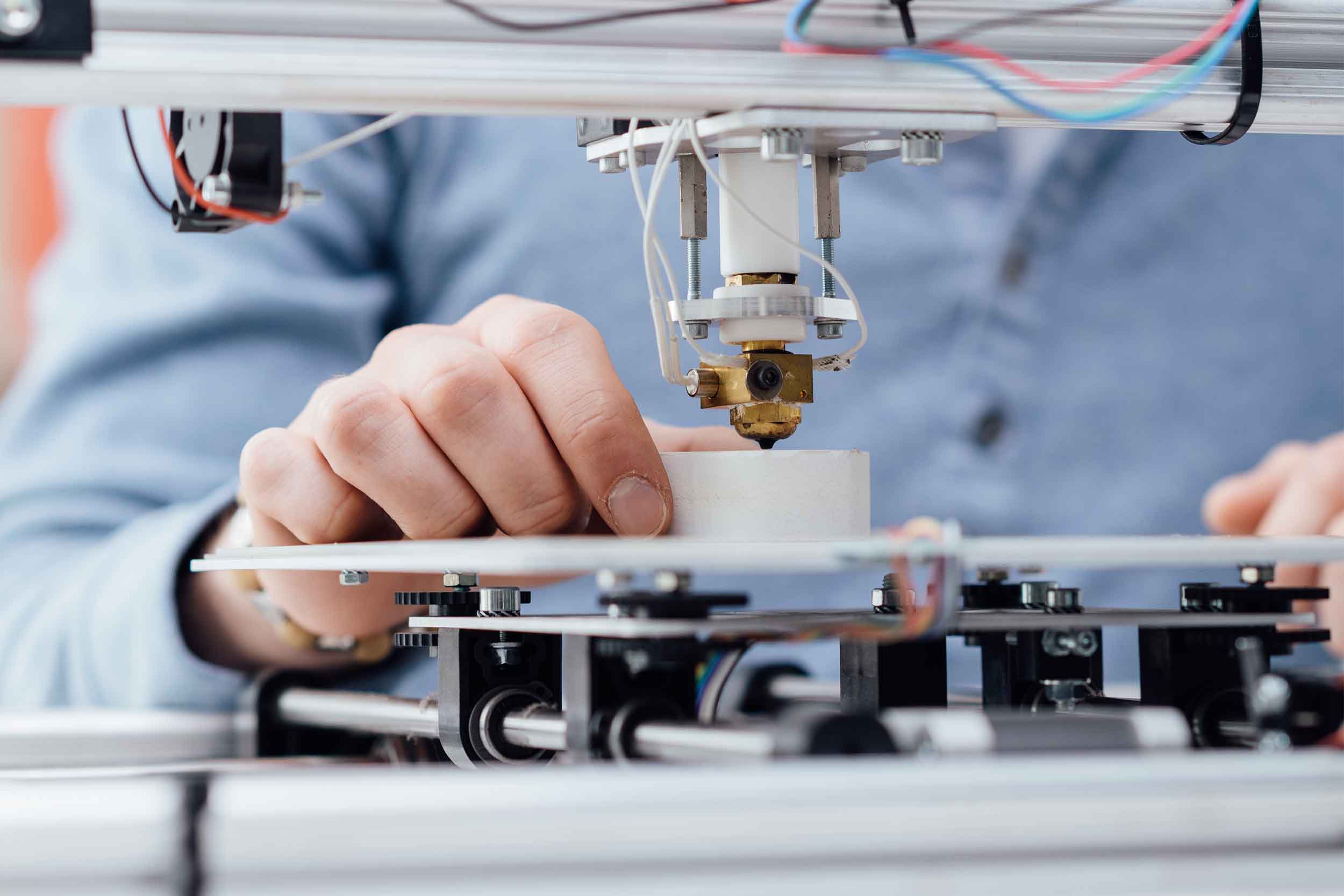

Mechanical Design

Innovative mechanical solutions engineered to perfection. Restricted with our quality tests.

Electrical Design

Cutting-edge electrical system design for reliability and efficiency. Refurbish your equipment.

Our Impact

From Costa Rica to the Medical Device Industry

ElectroAutomatización is not just automation machine manufacturers ; we are an engine driving progress and prosperity in Costa Rica and the United States.

EACR

Our impact extends beyond technology, encompassing economic growth and job creation. Our automatic machinery solutions foster innovation and competitiveness.

EACR

We play a pivotal role in shaping the future of automated manufacturing equipment. Whether optimizing processes, enhancing product quality, or ensuring reliability.

EACR

Our cutting-edge automation, meticulous design, and quality commitment enhance precision, productivity, and regulatory compliance for medical device manufacturers.

EACR

Fill out the form for a personalized quote

GET IN TOUCH CONTACT

CONTACT US NOW

We are automation machine manufacturers lets us know your engineering ne eds. Our team is available to answer any questions.

Our presence fuels medical device sector growth, attracting global investments, expanding local talent, and ensuring competitiveness and employment opportunities.