Precision Redefined: Unleash the Power of CNC Machinery

CNC Machine

fill out this form

ELECTROAUTOMATIZACIÓN

CNC Machine

In the dynamic world of manufacturing and precision engineering, Computer Numerical Control (CNC) machinery has emerged as a revolutionary force.

CNC milling machines are advanced tools that have reshaped the landscape of manufacturing, bringing unparalleled precision, efficiency, and versatility to the forefront of industrial processes.

CNC machinery stands as a testament to the evolution of manufacturing technology. The integration of computerized control systems has revolutionized the precision engineering landscape, offering unparalleled accuracy, efficiency, and versatility.

Computerized system

Industrial processes

Manufacturing Technology

Rigorous

Quality

Testing

CNC Machinery

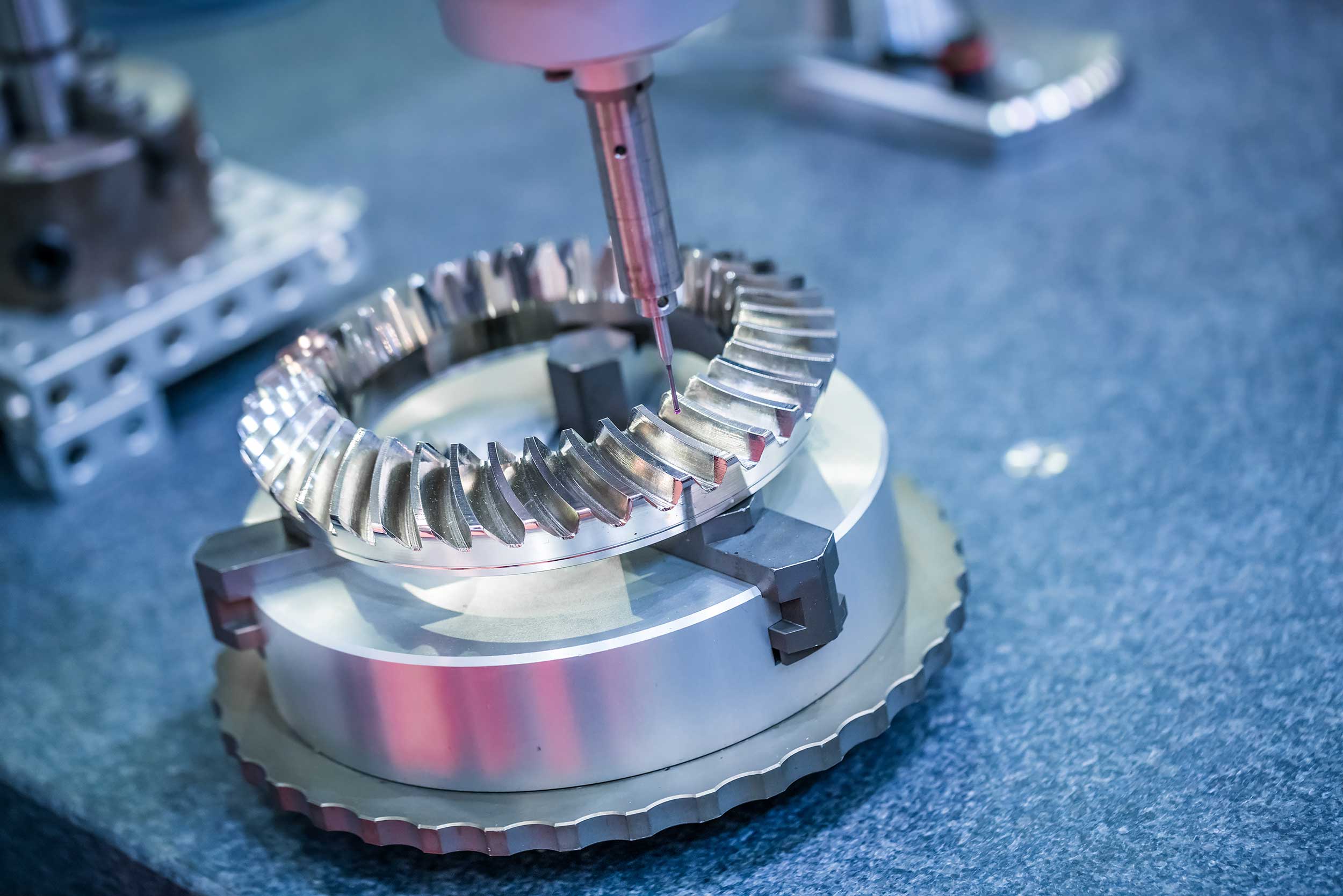

Precision in Rotation

At the heart of many machining operations is a versatile and efficient tool designed for turning and shaping materials. The CNC lathe employs computer-controlled movements to rotate a workpiece against cutting tools, allowing for the creation of complex shapes with unparalleled precision.

CNC Machinery

The Evolution of CNC Machinery

Computer Numerical Control machinery represents a significant leap in manufacturing technology. Unlike traditional manual methods, CNC machines rely on computerized systems to control and execute intricate tasks with remarkable accuracy. This paradigm shift has elevated production processes across various industries, ranging from aerospace to automotive and from medical to consumer electronics.

These machines have become indispensable in:

- Modern manufacturing landscape

- Showcasing the prowess of automated processes

- Digital precision

- High Quality surface finish

At EACR, we rely on the latest technologies available. Our partnership with the HAAS brand has been invaluable in providing us with training and continuous improvement in our CNC machining processes.

The integration of sensors, connectivity, and data analytics into CNC systems enables real-time monitoring, predictive maintenance, and adaptive machining strategies. This not only enhances efficiency but also contributes to the development of intelligent, self-optimizing manufacturing processes.

CNC lathes excel at crafting symmetrical parts like shafts and pulleys, working seamlessly with metals, plastics, and composites in various industries.

The precision achieved ensures consistency in the production process, reducing waste and enhancing the overall quality of manufactured components.

The of advent technology has not only accelerated production but has also opened up new possibilities in design and customization.

Complex geometries and intricate patterns can be effortlessly reproduced, pushing the boundaries of what was once thought possible in traditional machining.

Manufacturing landscape

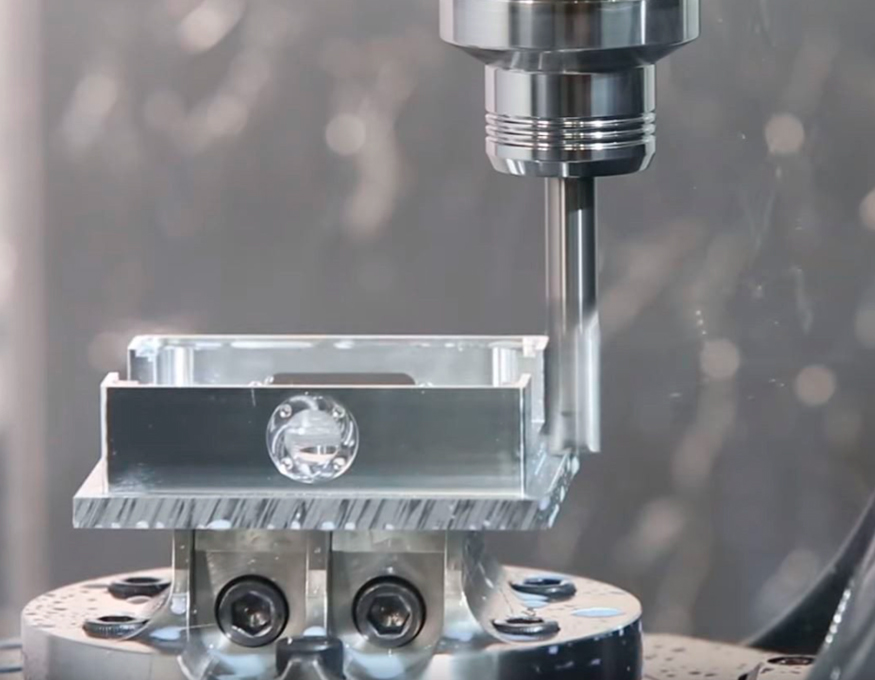

CNC Milling Machine: Sculpting the Future

In tandem with CNC lathes, CNC milling machines play a pivotal role in the manufacturing landscape, adding a dimension of versatility and complexity to the production process. Unlike the rotational nature of lathes, milling machines employ multi-axis movements to cut and shape materials in three-dimensional space.

CNC milling machines are capable of creating a wide array of components, from simple flat surfaces to intricate and detailed 3D structures. The computer-controlled precision of these machines ensures that each cut is executed with meticulous accuracy, meeting the exact specifications of the design.

Adaptability

Flexibility

The flexibility of CNC milling machines extends to the variety of materials they can handle, including metals, plastics, and composites. This adaptability makes CNC milling machines indispensable in industries where intricate and complex parts are the norm, such as aerospace, automotive, and medical device manufacturing.

Compatible with the present

Engineers and designers can now seamlessly transform their conceptual ideas into tangible reality with unparalleled ease. They can approach their projects with confidence, knowing that CNC machines will meticulously and faithfully replicate their visions with precision and accuracy.

Quality

Manufacturers can rely on CNC technology to deliver precision at scale, reducing the margin of error and minimizing material waste. This level of consistency is particularly crucial in industries where safety and reliability are paramount, such as in the production of critical aerospace components.

The Impact on Manufacturing

The incorporation of CNC machines has wielded a transformative influence on the manufacturing landscape, notably marked by a substantial reduction in production timelines. The remarkable precision and swiftness inherent in CNC operations facilitate expeditious prototyping and the seamless execution.

Why Choose Us?

When you choose ElectroAutomatización for obtaining a CNC Machine, you’re partnering with a team dedicated to exceeding your expectations. Our commitment to precision, versatility, and state-of-the-art equipment ensures you receive top-quality components and services for your projects. Contact us today to experience excellence in the CNC Machine.

EACR

Our impact extends beyond technology, encompassing economic growth and job creation. Our automatic machinery solutions foster innovation and competitiveness.

EACR

We play a pivotal role in shaping the future of automated manufacturing equipment. Whether optimizing processes, enhancing product quality, or ensuring reliability.

EACR

Our cutting-edge automation, meticulous design, and quality commitment enhance precision, productivity, and regulatory compliance for medical device manufacturers.

EACR

Our presence fuels medical device sector growth, attracting global investments, expanding local talent, and ensuring competitiveness and employment opportunities.